|

Hohman Plating & Mfg., Inc. - www.hohmanplating.com

- 1401 Abalone Avenue, Dayton OH 45404 USA,

email, Tel. +1 937 228 2191

Our facility consists of 7 buildings with a total manufacturing area of 90,000 square feet, including 15 electroplating lines, R&D laboratory, a Quality Assurance-Inspection laboratory, a Division of Environmental Safety with a state-of-the-art wastewater treatment facility, and the Vacuum and Plasma Coatings Division.

|

|

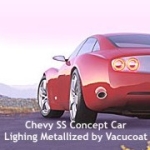

products: Vacuum Coatings

The Vacuum Coatings Division of Hohman Plating provides coating solutions for many different applications, including friction and wear resistant coatings, as well as high performance hard coatings. This division alone has coated well over one million parts for the Aerospace industry, pioneering many coatings that have become industry standards, such as MoS2.

Hohman's many different vacuum coatings are achieved using various Physical Vapor Deposition (PVD) processes. PVD is an environmentally friendly process, which produces very thin, extremely dense and well adherent coatings. More specifically, PVD is an atomic deposition in which a material is vaporized from a solid (or liquid) source and then transferred in vapor form through a vacuum environment to the part's surface where it condenses.

The various PVD processes performed at Hohman Plating are listed below

- Cathodic Arc Ion Plating: This low temperature, high energy process is used to produce hard wear coatings such as TiN, TiCN, TiC, CrN, and TiAlN.

- Sputtering: This process offers superior adhesion of the coatings and is used by Hohman for applying solid film lubricants such as MoS2, including several advanced versions.

Electron Beam Ion Plating: This process is perhaps the most versatile of all, and is often the solution to many coating challenges. Ion Plating can be used to deposit many coatings and combinations. Examples include Pb, Ag, Au, Ni, Pt, Cu, etc.

|